Factory Free sample 2 naphthol msds - HH-3302 waterborne epoxy anticorrosive paint – Mit-ivy

Factory Free sample 2 naphthol msds - HH-3302 waterborne epoxy anticorrosive paint – Mit-ivy Detail:

|

Product name |

HH-3302 waterborne epoxy anticorrosive paint |

|

Conventional colors |

iron red, gray |

|

Packing specification |

main paint 20kg + curing agent 3.3kg/group |

|

Mixing ratio |

6:1 |

|

Theoretical coating rate |

5.7㎡/kg, 60μm |

|

Typical film thickness |

dry film 60-120μm/wet film 125-250μm |

|

Overview |

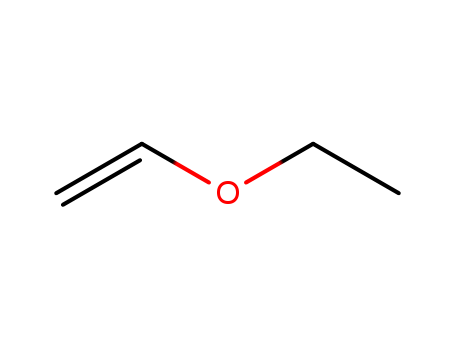

HH-3302 two-component water-based epoxy anticorrosive paint, composed of water-based epoxy resin, anti-rust pigment, polyamide and other components, widely used in areas with high requirements for heavy corrosion and corrosion resistance, the paint is suitable for steel , Carbon steel, cast iron and other substrates. |

|

Product characteristics |

Water-based environmentally friendly products, using water as a diluent, safe and stable in storage and construction, non-flammable and non-explosive. Excellent anti-corrosion and anti-rust performance, Good surface adaptability and constructability |

|

Recommended |

use Suitable for protective primers in moderate to severe corrosive environments, long-term corrosion protection for steel.It can also be used in maintenance packages.Can be used with most of the coatings in….steel structures, bridges, mechanical equipment, petrochemical plants, power plants, engineering machinery, industrial vehicles, chemical containers and other industrial fields |

|

Common supporting primer |

HH-3302 waterborne epoxy paint |

|

Topcoat |

HS-6301 waterborne acrylic polyurethane topcoat |

Product Features.

(1) Water-based antirust paint, non-toxic, tasteless, non-polluting, no harm to human health, truly green.

(2) Water-based antirust paint, non-flammable and non-explosive, easy to transport.

(3) Water-based antirust paint, diluted with tap water, construction tools, equipment, containers with tap water cleaning, greatly reducing the cost of painting.

(4) Waterborne antirust paint, fast drying time, improve work efficiency and reduce labor costs. Applicable scope: Automobile, ship, net frame, machinery manufacturing, container, railway, bridge, boiler, steel structure and other industries.

Construction instructions

1、It is forbidden to contact with oily substances, stir well before use, add water to dilute according to the actual needs, but generally add 0-10% of water is best.

2、Brushing, roller coating, spraying, dip coating can be applied, the construction temperature ≥5℃.

3. Before construction, remove the surface oil, sand, debris, loose floating rust, and the thickness of the rust layer should not exceed 120 microns.

4. The storage temperature should be ≥0℃, stored in a cool and dry place, freeze proof and sun proof, and the shelf life should be 18 months.

Development trends editor

With society’s low-carbon environmental protection concept of continuous advancement, water-based environmentally friendly coatings will inevitably become the future development trend, according to related research, water-based antirust paint has great room for development, from China’s overall economic development, the next three to five years, water-based antirust paint will appear a leapfrog development.

Yellow Editor

Sometimes a yellowing of the paint coating can occur if the construction is not done correctly, and if the paint is freshly sprayed, the cause can be due to several reasons.

1. unclean mixing equipment

2. a deteriorated paint was used, its clarity is low and the quality of the hardener is too poor. In the case of original paint the reasons could be.

a. Thin layer of topcoat

b. Contamination of the hardener and failure to produce a chemical change (handover)

c. Using a deteriorated primer.

3. we remind buyers that in the domestic painting industry, it’s always worth every penny, so don’t buy some cheap paint, it may cost more, once the paint problem is lost

Ben isn’t just the cost, but also the labor.

Here are three ways to prevent it

1. ensure that all mixing equipment meets the requirements; any paint purchased from our company must be applied according to the methods and techniques we provide

2. spray in strict accordance with the information provided in the technical specifications, do not add or reduce the additional material.

3. seal the lid well after use to prevent moisture from entering.

4. If repainting is required, it must be sanded and cleaned and then repainted.

The main series of water-based industrial paints are as follows.

1. Water-based paint series for vehicles

2. Water-based paint series for steel structure

3. Wind power equipment water-based paint series

4. Water-based container paint series

5. Automotive water-based paint series

6. Water-based marine paint series

7. Water-based industrial paint series

8.Water-based fireproof coating series

9. Water-based wood paint series

Water-based paint instead of solvent-based paint is the need to save energy and reduce emissions, is the protection of the environment, purify the air, to protect people’s health needs, is the need for safe production and construction, is to improve the survival and development of human needs!

Product detail pictures:

Related Product Guide:

Mit-ivy industry Flocculant for paint fog waste water treatment Paint fog flocculant to treat paint waste water Water treatment chemicals for spray booth

List of flammable and explosive chemical reagents commonly used in laboratories

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for Factory Free sample 2 naphthol msds - HH-3302 waterborne epoxy anticorrosive paint – Mit-ivy , The product will supply to all over the world, such as: Jeddah, United Arab Emirates, Costa Rica, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!