Good Quality metal paint remover - Paint mist coagulant – Mit-ivy

Good Quality metal paint remover - Paint mist coagulant – Mit-ivy Detail:

Functional Overview

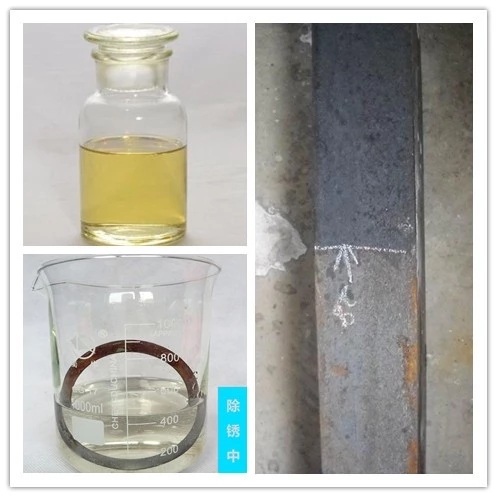

Water-based paint is difficult to separate from water due to its miscibility with water, and it produces a lot of foam, which affects production. Water-based paint mist coagulant is a kind of chemical agent raw material specially used to deal with the treatment of water-based paint waste water and the removal of paint (paint slag) in circulating water. Water-based paint mist coagulant is a common additive for spray treatment of circulating water in the paint industry. The main function is to eliminate the viscosity of the paint mist, condense the paint mist into floc and float it on the surface of the circulating water, which is easy to salvage and remove (or automatically control the slag removal).

|

1. Decompose and remove the viscosity of falling paint in the circulating water of many types of water curtain spray booths |

2. Coagulate and suspend the paint residue |

|

3. Control microbial activity of circulating water and maintain water quality |

4. Enhance the service life of circulating water, reduce the cost of cleaning tank and water |

|

5. Improve wastewater biochemical treatment capacity and reduce wastewater treatment costs |

6. Paint slag is non-sticky and odorless, easy to dehydrate and reduce the cost of discarded slag |

|

7. Maintain supply and exhaust balance, improve production efficiency, ensure product quality, and reduce production costs |

8. Paint spraying room is easy to clean and maintain, increase service life and reduce equipment replacement cost |

|

9. Improve the working environment of spray booth and work efficiency |

|

Instructions Overview

Water-based paint mist coagulant is divided into agent A and agent B. The two agents are used together (generally the ratio of agents A and B is 3:1–2). First add a certain amount of agent A (generally 2‰ of the amount of paint circulating water) in the paint circulating water. Agent A is added at the inlet of the circulating water, and agent B is added at the outlet of the circulating water for painting (agents A and B must not be added at the same place at the same time). Generally, the dosage of the agent is 10-15% of the amount of overspray. Usually, the agent can be added manually or automatically by the metering pump. According to the amount of overspray, the flow rate and displacement of the metering pump can be adjusted.

| specification | appearance | Density (20°C) | PH (10g/L) | Refractive index (20°C) |

| A-agent | paste-like liquid | 1.08±0.02 | 7±0.5 | 1.336±0.005 |

| B- agent | Viscous liquid | 1.03±0.02 | 6±0.5 | 1.336±0.005 |

Instructions

1. It is recommended to completely clean the tank and change the water once before using the agent, so that the effect will be better. After changing the water, first adjust the water quality with sodium hydroxide to control the 8-10PH value range, and add 1.5-2.0 kg per ton of water Around sodium hydroxide.

2. Add paint mist flocculant A to the turbulent water circulation of spray booth every morning after water change (ie, spray booth pump motor); after adding the medicine, produce and spray paint as usual, and add paint mist flocculant B before work. The paint residue is usually salvaged (that is, the poly paint tank); the suspended paint residue can be salvaged after work.

3. Dosing ratio: The dosing ratio of paint remover and suspending agent is 1:1, and each time the amount of paint sprayed in the circulating water of the spray booth reaches 20-25 kg, add 1 kg each. (This ratio is a pre-estimated value. The actual dosage needs to be adjusted slightly according to the type of paint and viscosity on site. Because the old paint block adsorbed in the spray room pipeline will consume part of the potion, so the amount of drug used in the initial period of dosing should be slightly. Too large)

4. No need to adjust PH value.

Handling and storage

1. Avoid splashing the liquid into the eyes. If contact with the liquid, immediately flush the contact area with plenty of water.

2. Store paint flocculant AB in a cool place and avoid direct sunlight.

3. Cannot be stored in alloys of aluminum, iron and copper.

![]()

Product detail pictures:

Related Product Guide:

Mit-ivy industry Flocculant for paint fog waste water treatment Paint fog flocculant to treat paint waste water Water treatment chemicals for spray booth

CAS No. [95-68-1] Production process. 2,4-Dimethylaniline

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for Good Quality metal paint remover - Paint mist coagulant – Mit-ivy , The product will supply to all over the world, such as: Uganda, Spain, Paraguay, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.