Entering 2023, the domestic epoxy resin continues to expand capacity, but the downstream demand recovery is less than expected, the contradiction between market supply and demand is highlighted, and the market price as a whole shows a downward trend. The narrowing of epoxy resin profit margin and the decline of industry capacity utilization have become the characteristics of market operation in the first half of 2023, but the export volume of epoxy resin has increased significantly compared with the same period last year, and the import has decreased significantly. What are the new situations in the follow-up epoxy resin market to be concerned about, and how will the future market develop?

Analysis of the operation characteristics of epoxy resin market in the first half of 2023:

1. New production capacity of epoxy resin continues to be released, and domestic production increases

According to Longzhong information monitoring data statistics, from January to June 2023, the domestic epoxy resin production capacity expanded to 3.182,500 tons/year, and three new enterprises were added, Zhejiang Haobang Phase II 80,000 tons/year, Anhui stellar 25,000 tons/year, Dongying Hebang 80,000 tons/year, with a total new production capacity of 185,000 tons. The monthly production capacity of resin increased to 265,200 tons, an increase of 16.98%.

2, epoxy resin prices down, the overall volatility is relatively moderate

Since 2023, the price center of gravity of domestic epoxy resin has fluctuated downward. According to the monitoring data of Longzhong Information, as of June 30, the mainstream negotiation of liquid epoxy resin in East China was 12,000-12,500 yuan/ton, down 2,700 yuan/ton from the beginning of the year, down 18.12%; The mainstream negotiation price of solid epoxy resin in Huangshan region is 12,000-12,500 yuan/ton, down 2,300 yuan/ton from the beginning of the year, down 15.97%. In the first half of the year, the mainstream market fluctuation range was 12,000-15,700 yuan/ton, with a maximum amplitude of 3,700 yuan/ton, while in the same period last year, the fluctuation range was 20800-29300 yuan/ton, with a maximum amplitude of 8,500 yuan/ton. In contrast, the price fluctuation of the resin market in the first half of 2023 was significantly lower than in the previous period.

3, the gross profit margin of epoxy resin has shrunk significantly, and the utilization rate of liquid capacity has decreased significantly

In the first half of 2023, the growth of terminal consumption is less than expected, the contradiction between supply and demand of epoxy resin is prominent, and the market price is overall downward. Although the center of gravity of raw materials is also weak, the decline is significantly smaller than that of epoxy resin, and epoxy resin has entered a state of loss since February. At the end of June, the loss peaked at 788 yuan/ton for liquid epoxy resin and 657 yuan/ton for solid epoxy resin. Due to the serious loss of profits in the industry, liquid epoxy resin manufacturers have reduced production and negative quotes, some manufacturers took the opportunity to overhaul, and the capacity utilization rate of the liquid epoxy resin industry continued to decline, falling to within 40% in June.

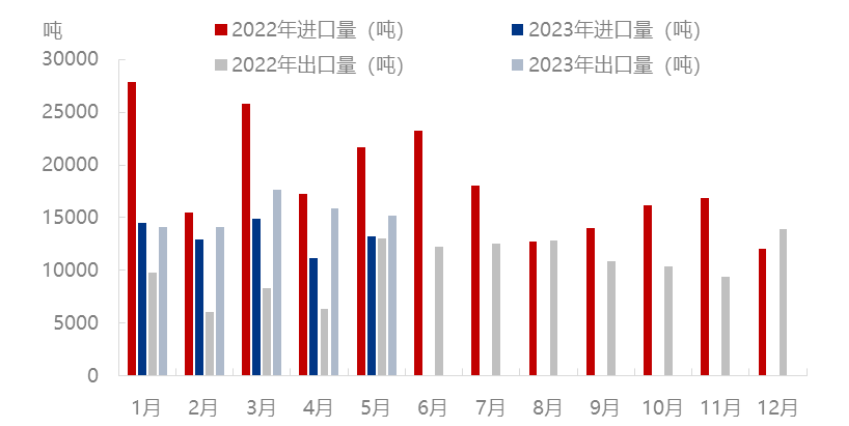

4, epoxy resin imports have shrunk sharply, but exports have risen sharply

According to the monitoring data of Longzhong Information, the total import of epoxy resin in China from January to May was 66,600 tons, a sharp decline of 38% from the same period last year. According to the analysis, the expansion of China’s epoxy resin production capacity, a substantial increase in domestic supply, and a decline in the dependence of epoxy resin on imports are the main reasons for the decline in China’s epoxy resin imports. Exports have increased significantly, and exports have become an effective way to consume domestic epoxy resins. From January to May, the total export of epoxy resin reached 76,900 tons, an increase of about 77% over the same period last year.

At present, it has entered the second half of the year, and the price center of gravity of epoxy resin has rebounded and risen under the support of cost, but there is no substantial improvement in downstream demand. Market supply, cost and downstream demand follow up remains to be seen.

1. Supply side: The supply of epoxy resin products is expected to increase

According to the monitoring data of Longzhong Information, after the end of 2023, there are still more than 350,000 tons of new production capacity of epoxy resin planned to put into production, when China’s epoxy resin production base continues to expand, the domestic supply will also grow.

2. Cost: general support

In the second half of 2023, bisphenol A is still in the centralized capacity expansion cycle, and more than 1.5 million tons/year of equipment is planned to be put into production, while another raw material epichlorohydrin also has capacity expansion, and the oversupply of double raw materials will continue, and most companies expect the market to narrow in the second half of the year. Overall, the support of double raw materials for the epoxy resin market is general.

3, demand: just need to follow up, it is difficult to substantially improve

From the consumer side, epoxy resins are mainly concentrated downstream in wind power, copper clad panels, coatings and so on. However, in the second half of the year, the final consumption of epoxy resin still lacks bright spots. From the perspective of the wind power industry, in 2022, China’s wind power manufacturers won a total of 446 projects, a total of 86.9GW, an increase of 60.63%, a record high, including land wind 71.2GW, sea wind 15.7GW. Taking into account the construction cycle of about one year after the completion of wind power bidding, the bank expects that the new installed capacity of land wind is expected to exceed 55GW in 2023, an increase of about 60%. Wind new installed capacity of more than 10GW, more than doubled year-on-year, wind power demand for epoxy resin is relatively stable, the market can still add some confidence. However, in terms of copper clad plates and coatings, the demand in the second half of the year from July to August is relatively weak, the demand for epoxy resins is reduced, and more need to be followed up, which is difficult to form favorable support for the market. Overall, in the second half of 2023, resin downstream terminal demand is difficult to have substantial bright spots.

Post time: Jul-24-2023