Reactive dyes have bright colors and complete chromatograms. It is known for its simple application, low cost, and excellent fastness. Especially with the development of cellulose fibers in recent years, reactive dyes have become the most important type of dye for cellulose fiber textile dyeing.

But the most prominent problem of reactive dyes is the low exhaustion rate and fixation rate. In the traditional dyeing process of cellulose fiber, in order to improve the dye uptake and fixation rate of reactive dyes, a large amount of inorganic salt (sodium chloride or sodium sulfate) must be added. Depending on the dye structure and color, the amount of salt used is generally 30 to 150 g/L. Although great progress has been made in the treatment of organic compounds in printing and dyeing wastewater, the addition of a large amount of inorganic salts in the dyeing process cannot be treated by simple physical and biochemical methods.

Research on the technology of reactive dyes and salt-free dye

From an ecological perspective, the discharge of high-salinity printing and dyeing wastewater directly changes the water quality of rivers and lakes and destroys the ecological environment.

image

The high permeability of salt will cause the salinization of the soil around the rivers and lakes, reducing the yield of crops. In short, the use of a large amount of inorganic salts can neither be degraded nor recycled, and at the same time has a great negative impact on water quality and soil. Based on this, this article reviews the recent research progress of salt-free dyeing technology, and systematically discusses the structural changes of low-salt reactive dyes, grafting technology, and cross-linking technology.

Reactive dyes for salt-free dyeing

The outstanding features of reactive dyes are small molecular structure, good hydrophilicity, and easy washing off of floating color after fixing. This is an important innovation in the design of dye molecules. But this also causes the dye exhaustion rate and fixation rate to be low, and a large amount of salt needs to be added during dyeing. Lead to the loss of a large amount of salty wastewater and dyes, thus increasing the cost of wastewater treatment. Environmental pollution is serious. Some dye companies began to pay attention to the screening and improvement of dye precursors and reactive groups, and to develop reactive dyes for low-salt dyeing. CibacronLs launched by Ciba is a type of low-salt dyeing dyes that use different active groups to combine. The characteristic of this dye is that the amount of salt used in dyeing is 1/4 to 1/2 of that of general reactive dyes. It is not sensitive to changes in bath ratio and has good reproducibility. This type of dyes are mainly dip dyeing and can be used together with disperse dyes for fast one-bath dyeing of polyester/cotton blends.

Sumitomo Corporation of Japan proposed a set of dyeing methods suitable for Sumifux Supra series dyes. It is called LETfS staining method. The amount of inorganic salt used in this method is only 1/2 to 1/3 of the traditional process, and the bath ratio can reach 1:10. And launched a series of reactive dyes compatible with the process. This series of dyes are heterobi-reactive dyes composed of monochloros-triazine and B-ethylsulfone sulfate. The amount of residual dye in the dyeing wastewater of this series of dyes is only 25%-30% of the dye content in the general reactive dyeing wastewater. It is recommended for the dyeing of Tencel fibers. It shows excellent application performance in terms of fixation rate, easy washing, and various fastnesses of dyed products.

DyStar company launched the RemazolEF series dyes suitable for salt-free dyeing, the active group is mainly B-hydroxyethyl sulfone sulfate, and launched an environmentally friendly salt-free dyeing process. The amount of inorganic salt used is 1/3 of the conventional process. The dyeing process is shortened. In addition, the system covers a wide range of chromatograms. A variety of three primary colors can be combined to obtain bright colors. Clariant (Clariant) company launched the DrimareneHF series of reactive dyes, mainly in 4 varieties: DrimareneBlueHF-RL, 戡ownHF-2RL, NavyHF-G, RedHF-G, used for exhaustion dyeing and continuous dyeing of cellulose fibers, application performance And good fastness. The fixation rate is quite high, low salt and low liquor ratio. Neutral fixation, good washability.

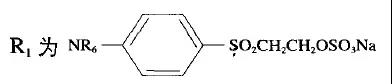

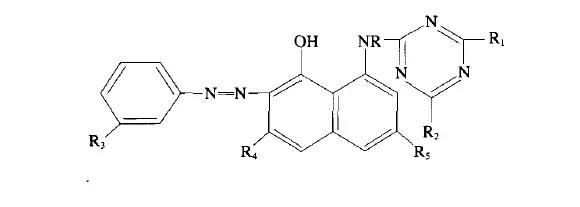

Some newly developed reactive dyes can increase the directness of dyes by increasing the volume of dye molecules and reduce the amount of inorganic salts. For example, the introduction of urea groups can increase the directness of active groups and reduce the amount of inorganic salts. Improve the fixation rate; there are also polyazo dye precursors (such as trisazo, tetraazo) to increase the directness of the dye, and achieve the purpose of salt-free dyeing. The high steric hindrance effect of some dyes in the structure can also significantly change the reactivity of the reactive groups of reactive dyes and the amount of salt used in dyeing. These steric hindrance effects are generally the introduction of alkyl substituents at different positions on the dye matrix. Their basic structural features are summarized by scholars as follows:

Active group one SO: CH2CH: oS03Na can be in the meta or para position of the benzene ring;

R3 can be in the ortho, inter, or para position of the benzene ring. The structural formula is vinyl sulfone reactive dyes.

Different substituents or different substitution positions on the dyes can achieve the same dyeing value under the same dyeing conditions, but their dyeing salt amounts are quite different.

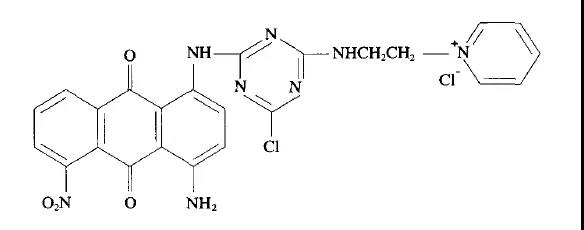

Excellent low-salt reactive dyes must have the following characteristics: 1) The amount of salt used in dyeing is greatly reduced; 2) Dyeing in a low bath ratio dye bath, dyeing bath stability; 3) Good washability. Reduce post-processing time; 4) Excellent reproducibility. In terms of dye improvement, in addition to the above-mentioned improvement of the dye matrix structure and reasonable combination of active groups, some people have synthesized the so-called cationic reactive dyes, which can be dyed without adding salt. E.g. Cationic reactive dyes of the following structure:

It can be seen from the above formula that the color body is connected to the active group of monochloro-triazine. A pyridine quaternary ammonium group is also attached to the s-triazine ring. The dye is positively charged and the quaternary ammonium group is a water-soluble group. Since there is not only no charge repulsion between the dye molecules and the fiber, but also the attraction of positive and negative charges, the dye is easy to approach the fiber surface and adsorb to the dyed fiber. The presence of electrolytes in the dyeing solution will not only not produce the dye-promoting effect, but also weaken the attraction between the dye and the fiber, so this type of dye dyeing can be dyed without adding electrolytes for salt-free dyeing. The dyeing process is similar to ordinary reactive dyes. For monochloros-triazine reactive dyes, sodium carbonate is still added as a fixing agent. The fixing temperature is around 85℃. The dye uptake rate can reach 90% to 94%, and the fixation rate is 80% to 90%. It has good light fastness and washing fastness. Similar cationic reactive dyes have also reported using monofluoro-s-triazine as the active group. The activity of monofluoro-s-triazine is higher than that of monochloro-s-triazine.

These dyes can also be dyed in cotton/acrylic blends, and other properties of the dyes (such as leveling and compatibility, etc.) need to be further studied. But it provides a new way for cellulose fiber to carry out salt-free dyeing.

Post time: Jan-12-2021