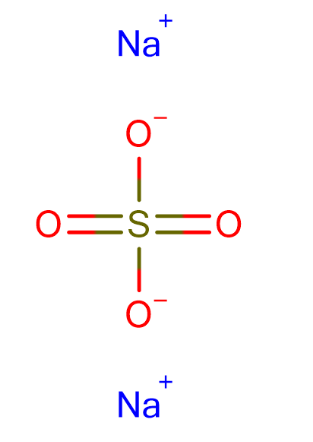

Yuanming powder is also called Glauber’s salt, and its scientific name is sodium sulfate. This is an inorganic salt that is very close to the chemical properties of table salt.

1. Used as a direct dye and other accelerating agent for cotton dyeing

When dyeing cotton with direct dyes, sulphur dyes, vat dyes and Yindioxin dyes, sodium sulfate can be used as a dye-promoting agent.

These dyes are easy to dissolve in the prepared dyeing solution, but not easy to dye cotton fibers. Because the dye is not easy to be exhausted, there is a lot of dye remaining in the foot water.

The addition of sodium sulfate can reduce the solubility of the dye in water, thereby increasing the coloring power of the dye. In this way, the amount of dye can be reduced, and the dyed color will be deepened.

1. The amount of sodium sulfate

It depends on the coloring power of the dye used and the depth of the desired color. Don’t add too much or too fast, otherwise the dye in the dye solution will precipitate and cause dye spots on the cloth surface.

2. When dyeing cotton fabric

Yuanming powder is generally added in batches in the 3rd to 4th steps. Because the dye solution is very thick before dyeing, if it is added quickly, the dye will dye on the fiber too quickly and it is easy to produce unevenness, so dye it for a while and then add it. Proper.

3. Sodium sulfate before use

Yuanming powder should be fully deepened with water before use, and filtered before being added to the dyeing bath. It is more necessary to stir the dyeing bath and slowly add it to prevent the partial dyeing bath from contacting a large amount of accelerant and causing the dye to salt. Analyze role.

4. Sodium sulfate and salt are commonly used dye accelerators

Practice has proved that in direct dyeing, using sodium sulfate as a dye accelerator can get a bright color. The effect of using table salt is poor, which is related to the purity of table salt. In addition to more calcium and magnesium ions, general industrial salt also contains iron ions. Some dyes that are greatly affected by iron ions (such as direct turquoise blue GL, etc.) use salt as a dye accelerant, which will cause the color to be gray.

5. Some people think that the price of table salt is cheaper

Some people think that the price of table salt is cheaper, and table salt can be used to replace Yuanming powder. However, it is better to use Yuanming powder for light color than table salt, and for dark color, table salt is better. Whatever is appropriate, it must be applied after testing.

6. The relationship between sodium sulfate and the amount of salt

The relationship between sodium sulfate and salt consumption is roughly as follows:

6 parts anhydrous Na2SO4=5 parts NaCl

12 parts hydrate Na2SO4·10H20=5 parts NaCl

2. Used as a retarder for direct dyeing and silk dyeing

The application of direct dyes on protein fibers is mostly silk dyeing, and the dyeing fastness obtained is better than that of general acid dyes. Some direct dyes also have excellent dischargeability, so they are often used for discharge of ground color in silk fabric printing.

Direct dyeing of silk also often adds a small amount of sodium sulfate, but the role of sodium sulfate is different from that of cotton dyeing. It only acts as a slow dyeing agent.

Note:

1. Dyeing silk with direct dyes. After sodium sulfate is added, the slow-dyeing effect occurs as follows:

The direct dye R SO3Na dissociates into sodium ion Na+ and pigment anion R SO3- in water, as shown in the following formula: RSO3Na (interconversion arrows in parentheses) Na+ R SO3- yuanming powder Na2SO4 dissociates into sodium ion Na+ and sulfate ion SO4- in water -, the following formula: Na2SO4 (interconversion arrows in parentheses) 2Na+ RSO4–In the dyeing bath, the dye anion R SO3- can directly dye silk. When sodium sulfate is added, it will dissociate to produce sodium ion Na+, The dissociation of the dye is affected by sodium ions; that is to say, because of the equilibrium relationship of the post-ion reaction, it is affected by the Na+ common ion guilt, which reduces the dissociation of the dye, so the dyeing of silk is slowed down. Dyeing effect.

2. For fabrics dyed with direct dyes, generally use fixing agent Y or fixing agent M (about 3~5g/l, 30% acetic acid 1~2g/l, temperature 60℃) for 30 minutes to improve the finished product Color fastness.

4. Used as ground color protectant for scouring of printed and dyed silk fabrics

When scouring printing or dyeing silk fabrics, the dye may be peeled off, so that it will stain the ground color or other synchronized fabrics. If sodium sulfate is added, the solubility of the dye can be reduced, so there is no danger of peeling off the dye and contaminating the ground color. Up.

Post time: Jun-25-2021