Water Based Epoxy Ester Primer and Topcoat 2- in- 1

Product introduction

Product features

* With water as the dispersion medium, non-flammable, non-explosive

* Harmless to human health

* Convenient construction, fast drying, high construction efficiency

* Good mechanical strength

* Excellent low temperature stability

* Excellent weather resistance and decoration

Application

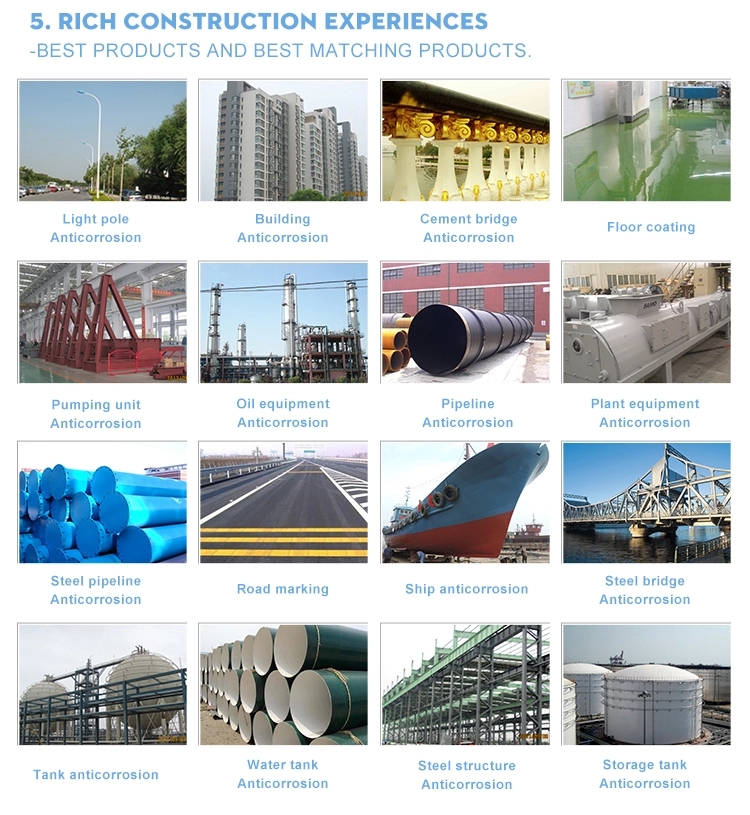

* Used on the surface of iron and steel materials for rust prevention and decoration

* Manufacture and maintenance of ships, railway vehicles, automobiles, agricultural vehicles and other transport vehicles

* Oil field and petrochemical machinery, pipelines, storage tanks

* Machinery and equipment in metallurgy, electric power, textile, food and other industries

* Bridge, iron tower, grid and other steel structures

Painting interval

Substrate temperature 10℃ 20℃ 30℃

Shortest

4h 2h 1h

Maximum

Unrestricted

Surface treatment

Sand blasting or grinding to Sa2 or St3 level, that is, completely remove oil stains, rust and old paint film on the surface of the substrate

Packing specification

20kg/barrel

25kg/barrel

Storage life

0-40℃, 6 months

Transport

According to the transport of non-dangerous goods

Note

1. This product is water-based paint, can not be mixed with organic solvents or solvent based paint.

2. Mix well before use and adjust viscosity with appropriate amount of water.

3. When diluting the product, gradually add water to dilute it to the construction viscosity.

4. Wash tools with water immediately after use.

5. It is not suitable for construction when the temperature is lower than 0℃ and the relative humidity is higher than 85%.

| Standard Parameters of Water based epoxy ester primer and topcoat 2 in 1 | ||

| Items | indicator | |

| Status in the container | Viscous liquid,No hard lumps after stirring | |

| Color and Apperance of paint film | normal | |

| Outflow time(ISO6#cup)/s ≥ | 45 | |

| Solid content%≥ | 45 | |

| Fineness, μm≤ | 35 | |

| drying time | hard dry,h | 24 |

| oven dry (120℃/1h) | pass through | |

| Hardness (Pencil) | HB | |

| Impact kg.cm | ≥50 | |

| Flexibility mm | ≤1 | |

| Adhesion/Grade | ≤1 | |

| storage stability | paint film is good,No hard lumps | |

| Flash rust inhibition | normal | |

| Salt spray resistant | No blistering ,No rust,No shedding | |

Main characteristics

1. Like all epoxy paint, powder and fade will occur when exposed to atmospheric environment, but these phenomena have no effect on the overall corrosion resistance.

2. Apply the product by brush or silver coating, it may be necessary to apply multiple passes to obtain the specified dry film thickness. Excessive coating thickness should be avoided, and the wet film thickness of a film formation should not exceed 150μm.

3. High salt spray resistance, excellent corrosion resistance, excellent oil resistance, water resistance, salt water resistance, solvent resistance: the paint film is tough and dense, and the substrate has good adhesion. The thickness of the paint film is above 85 microns, and the corrosion resistance is better.

4. Low temperature curing. This product is a water-based system, not suitable for low temperature environment, the temperature below 10C is not recommended for construction, because the product below 10C conditions, can not be fully cured, below 0C products will freeze, can not be used.

Construction description

1. Clean the oil, rust, old patent leather and other dirt on the surface of the substrate before painting to ensure that the surface of the substrate is clean and dry.

2. Grinding wheel is used to remove welding bumps, spatter, and hardened layer on the workpiece surface. All free edge acute angles after gas cutting, shearing or machining should be polished to R2.

3. Sand blasting to Sa2.5 level or power tool cleaning to St2 level, construction within 6 hours after sand blasting.

4. Brush painting and spraying can be used for construction, and the paint should be stirred evenly before painting. If the viscosity is high, an appropriate amount of deionized water can be added, and the amount of water added should not exceed 10%, and it should be stirred while adding to ensure that the paint is uniform.

5. Maintain good ventilation during construction, and do not recommend construction when the ambient temperature is lower than 5 ° C or the humidity is greater than 85%.

6. Rain, snow and fog weather can not be constructed outdoors, such as construction, can be taken to protect the paint film by covering it with tarpaulin.

Storage and transportation

1. The product should be sealed and stored in a dry and well-ventilated warehouse with a storage temperature above 5 ° C and below 35 ° C to prevent direct exposure to water and sunlight, isolate the fire source, and stay away from the heat source.

2. If the product meets the storage conditions, the storage period is one year from the date of production, and the storage period can be tested beyond the storage period. If it meets the standards, it can still be used.

3. During the transportation process, the product should be prevented from cold, rain and sunlight exposure, and should comply with the relevant provisions of the transportation department.

Surface treatment

1. All surfaces to be coated shall be clean, dry and non-polluting, all surfaces shall be evaluated and treated according to ISO8504:1992, and grease shall be removed according to the requirements of the SSPC-SPI solvent cleaning standard.

2. The areas that have been coated with primer and have peeling and damage are treated according to the necessary standards, and these parts are recoated with primer before coating. The steel structure, welds and damaged areas of the pre-painted workshop primer should be sandblasted, polished or sanded. If the workshop primer falls off on a large scale, it needs to be fully treated.

Notes

1.24 hours prior to installation, store material between 70°F to 75°F (21°C to 24°C) for best results

2.Substrate and ambient temperature should be between 70°F to 90°F (21°C to 32°C) for best results

3.For best results humidity should be between 50% and 70% R.H.

4.Moisture content should not exceed 3% for concrete substrates and 15% for wood substrates

5.Allow for proper joints in substrates and do not overcoat joints

6.Do not thin the coating

7.After surface preparation and prior to applying primer, use masking tape to tape off any areas that are not to be coated. Note: pay special attention to joints, bolt holes, areas of contact or abrasion, or hinges: tape off any area that does not require coating. Important: prior to material drying, remove tape.

8. This product should not be mixed with any oil-based paint or organic solvent.

9. the curing agents used for different paints should not be mixed.

10. It is forbidden to contact with acid and alkali in the process of paint preparation and coating.

11. Wear the necessary protective equipment at the construction site.

12、After the curing agent is prepared for this series of products, it should be used within the applicable period under the condition that there is no pollution.

Company Information

MIT-IVY INDUSTRY CO.,LTD is a manufacturer and exporter of fine chemical dyes & pharmaceutical intermediates in China.

Mainly produce aniline series products and chlorine series products.

MIT –IVY Chemicals Industry Co.,Ltd. is a leading manufacturerof chemical for 21 years with complete production equipment and meticulous management and maintenance of machinery.

We use advanced production technology and test methods to realize production, quality controlling to meet the standard. We have been approved by SGS, ISO9001, ISO140 01, GB/HS16949 and T28001.

Mit-Ivy main products include as the following:

API, pharmaceutical intermediates ,Dye intermediates, fine,speciality chemicals,Waterborne industrial paint and new energy materials.

Our main markets includes America, India, Africa, Indonesia, Turkey, South-east Asia, West Asia and so on. MIT-IVY Industry Main products shares 97% of the domestic market specializing in the production and management, We can supply the products with more competitive cost. with premium quality and price and welcome to consult. Our company has professional persons who major in chemical R&D and sicentific management, supply fine chemical products with high quality and close service, also supply custom-tailored products according to our clients’ requirement. We have a positive and self-motivated management work team with a common philosophy, caring and commitment through teamwork, our team strive to achieve success in delighting our clients and ourselves. we continuously innovate our products and improve our service, sales network. Hence, we initiate the first sale mode on net in China, which is the retail trade of small package bring along wholesale of diversified management modes. Our products are exported widely to South Korea, Vietnam, Australia, Europe and South America, highly recommended by our clients. We insist on the management creed “Market is our compass, Quality is our life, Credit is our soul”. Clients’ trust is our forward powder, their satisfaction is our struggling goal.

Brand Customer Service:

Our JIT customer service account team network in China develop and implement tailor-made concepts for the optimum supply of our customers with industrial and specialty chemicals.

Your advantages:

● Centralized customer service supports simplification of administrative procedures, resulting in time and cost saving.

● Our Chinese network and sophisticated logistics solutions ensure that chemicals of identical quality are supplied to customers with several manufacturing locations and contribute to security in planning and reliability of processes.

● Our processes are continuously optimized and adapted to our customers’ changing structures and requirements.

Superiority of Chemistry Logistics service:

Chemical logistic service is very professional and should be superior under UN regularity, especially for DGR Class series. We provide a special-purpose solution to optimize logistic and suitable packing group and labeling service for our principals. Our main Chinese ports with DGR chemical warehouses are to operate specialty chemical and apply all relative paperwork concerned.

Our distribution capabilities include:

● Flexible deliveries, intelligent solutions

● Anything from bulk shipments of thousands of tonnes down to the smallest shipment of packed goods and even samples.

● Bulk – storage and transport of powders and liquids – movement of goods in ships – powders and bulk liquids

● Pharma, feed and food storage to accredited standards

● Segregated materials by business unit and hazard classification

● Temperature controlled storage and transport

● Effective cost control

● Re-packing, drum filling, bagging, ripping and tipping

● Customer delivery KPI's on delivery fulfillment performance

If you are interested in getting more quotations,

please add WHATSAPP:0086-13805212761 or E-MAIL:info@mit-ivy.com

FAQ

Q. Are you factory or trading company?

A. We are a factory located in Fuan city, Fujian province, China .

Q. Are all colors are same price?

A.No, the price are different depend on the texture, availability, Ingredients and So on.

Q. Can you provide samples for quality checking before placing an order?

A. Samples are available upon request, but the shipping cost should be paid by customer.

Q. Is there a discount?

A. The discount will be given by the quantity.

Q. How about delivery time?

A. About 7-15 days after payment confirmed.

Q. What kind of payment terms you can accept?

A. We accept T/T, LC, Western Union and Paypal.