Water Based Inorganic Zinc Rich Primer

Product introduction

Product features

* Water based primer, zero VOC, comply with environmental requirements

* Fast drying speed

* High temperature resistance, continuous resistance to 400℃ high temperature

* Excellent oil and solvent resistance

* High hardness, strong mechanical wear resistance

* Strong adhesion and electrical conductivity

* Not affected by welding and cutting. No combustible volatilization during construction

* It has certain Marine pollution resistance

* It can be single coated or matched with other coatings

* Excellent cathodic protection and corrosion resistance

Application

This product is a high performance anticorrosive coating for steel structure, widely used in large indoor and outdoor steel structures.

Such as: pipelines, transmission towers, oil tanks, locks, Bridges, television towers and ships, coastal facilities, oil equipment and so on .

Substrate treatment

Sand blasting or shot blasting should be at least GB8923 88 sa2.5 with roughness of 25-50 microns. The surface of the local repair layer shall be polished to meet GB8923 88 st3.

Construction conditions

Coating temperature range : 5-40℃, relative humidity below 85%, substrate surface temperature above dew point more than 3℃, temperature and humidity should be measured near the substrate.

When the temperature of the substrate is higher than 40℃, it is recommended not to carry out coating construction.

Heavy rain, snow, sand and other bad weather can not be painted.

Packing specification

Group A: 20kg/barrel

Group B: 10kg/barrel

Storage

This product should be stored in a cool, dry, ventilated indoor warehouse, storage period of six months

Note

1 .After sandblasting, the surface is clean and oil-free. Construction shall be carried out within 4 hours.

2. This coating is a two-component coating system, mixing must be in the mixing group B slowly into a group, stirring mixing 15-20mins, enough stirring and curing, through 80-100 purpose sieve filtration rear can be constructed, keep continuous mixing while spraying .

3. Pay attention to adequate ventilation during construction in the storage tank.

4. Coating can be a surface coating, a layer of thin coating must be carried out to prevent a large number of bubbles in the film.

5. Dilute with water, no more than 2%.

6. Stored in ventilated, dry, cool environment, suitable temperature 0℃-40℃. Sealing to prevent direct sunlight, in winter should be heat preservation antifreeze.

7. This coating is water-based coating, non-flammable and non-explosive, still need to pay attention to health. In case of eye contact, flush with fresh water for at least 10 minutes and seek immediate medical attention.

| Standard parameters of water-based inorganic zinc-rich primer | ||

| Items | indicator | |

| Status in the container | normal | |

| Appearance of paint film | normal | |

| Drying time | Surface dry, min ≤ | 15 |

| Hard dry, min≤ | 45 | |

| Cross-cut test/Grade ≤ | 1 | |

| Storage stability [(50±2)℃, 14d | normal | |

| Volatile organic compound (VOC) content/(g/L)≤ | 200 | |

| Water resistance (240h) | normal | |

| Salt spray resistance (30d) | No blistering ,No rust,No shedding | |

| Heat resistance (400℃, 24h) | No blistering ,No rust,No shedding,slight discoloration is allowed | |

Product Application

1.Shake the ACCENT can to dissolve any sediment that has formed on the bottom. In case of catalyzation of the last coat, after shaking the container, pour the varnish into the application container, then add 10% IDRO2 and mix very well. Wait 10-15 minutes before application to allow any foam formed during shaking to dissolve and in the case of the catalyzed product, to allow its pre-airing.

2.Apply a generous coat of product (when using a roller, we recommend Carver MONACO or POSEIDONE), abiding by the times stated for sanding or over coating, in one of the following cycles.

3.For a cycle that will not change the colour of the wood: apply 2 or 3 coats of ACCENT using a roller or brush, always respect the sanding and re-coating times in the table.

4.For a cycle combined with a primer that will not change the colour of the wood: apply 1 or 2 coats of ACCENT in combination with one of the following products used as a primer:

5.FONDO 300 (see technical data sheet)

6.AQUAHIT Mat (see technical data sheet)

7.To carry out a rapid water cycle: apply ACCENT with our FAST water-based primer (see the technical data sheet of this product).

8.Any different cycle or applying method should be previously verified.

9.Use the floor polisher with abrasive pads, grain size #180-220. In case of Trio, use a grain size of 80-100.

10.For spray application with curtain coater or other industrial application method, contact the Carver Technical Assistance Service.

11.WEGCRIL HIDRO ERP 805 is ideal for adhesion on metallic substrates as casted iron, carbon steel and galvanized steel, providing excellent protection for noble autoparts as engine blocks, truck chassis, machinery and equipment and autoparts in general.

12.Apply with spray gun or by imersion. It is environmentally friendly because it is a WATERBORNE PRODUCT, in other words, its solvent is water.

Main characteristics

1. Can withstand high temperature 800-1200℃.

2. Green, zero VOC volatilization, no heavy metals.

3. The coating has high hardness, abrasion resistance, thermal shock resistance and strong bonding force with the matrix.

4. Self-curing at room temperature, strong adhesion with matrix, good anti-corrosion performance, long service life.

Construction description

After the cleaning of tools, the tools used should be immediately washed with water to prevent drying.

Precautions This product should not be mixed with any oil-based paint or organic solvent.

The paint film shall not be in contact with organic solvents and water before it is completely dried, and shall not be damaged by heavy pressure, bump and friction.

If the second recoating interval is long, it is necessary to sand it to increase the adhesion.

Construction personnel should wear necessary protective equipment.

Store for 12 months (indoor ventilated dry place 5-40℃), beyond this period, can still be used after testing qualified.

Handle with care, avoid bumping and avoid leakage

Packaging specifications According to user requirements, packaging different specifications.

Maintenance

1.Eliminate dust with ANTISTATIC CLOTHS and if necessary, use a vacuum sweeper with non-rotating, natural-fibre bristles, suitable for parquet.

2.For cleaning the parquet, use one of the following options:

Wipe with a soft cloth, soaked in a diluted DETER PARQUET solution (see the technical data sheet) and squeezed. According to the foot traffic the floor is exposed to, follow the wash with a treatment using a diluted solution of our POLISH PARQUET, used as special maintenance treatment (see the technical data sheets).

Wipe with a soft cloth, soaked in a diluted POLISH PARQUET solution, used for frequent/routine maintenance (see the technical data sheet) and squeezed.

Wipe with a soft cloth, soaked in a slightly diluted PRONTO POLISH PARQUET solution (see the technical data sheet) and squeezed.

Notes

1.Acclimatize and apply wood and product at a temperature between +15°C and +35°C. Make sure that the relative humidity in the room is from 35% to 75%.

2.Before application, make sure the hardener is completely dissolved in the finish (there is always a little increase of the mixture viscosity in comparison with the component 1 viscosity). Catalysed paint retains its effectiveness for 4 hours. After this period of time, the paint cannot be used.

3.Always adhere to the prescribed recoating and abrading schedule. When recoating with ACCENT without sanding, do not exceed the 12 hr interval from the previous coat. When sanding and recoating, do not exceed a 5-day interval. Should also this latter interval be exceeded, in order to ensure good adhesion it is necessary to perform careful sanding, wash the floor with a cloth soaked in IDROCLEANER and to add 5% of our DILUENTE GRIP (see the technical data sheet of this product) to the catalyzed finish.

4.After abrading, always vacuum and tack thoroughly.

5.To improve coating or to delay drying, especially in very hot weather, add 5-10% water to the catalysed varnish or 2% of our DILUENTE GRIP.

6.Adhere strictly to the recommended amounts. Matt varnishes tend to become glossy when rubbed, if applied in a very thin layer.

7.Before treating tropical woods or dark woods in general, it is advisable to perform a test beforehand to avoid undesired colour changes.

8.When refinishing old floors, and in all cases in which the wood is very dry, add 10% water to the first coat.

9.The finished surface can be cautiously walked on after 24 hours. It achieves the optimal mechanical resistance after 5-7 days.

Safety and health

Avoid contact with skin and eyes during use. If it comes into contact with skin, it should be quickly wiped off with a cloth and then washed with water. If contact with eyes, rinse with plenty of water and seek medical attention immediately.

Eating, smoking and other unsafe behaviors are prohibited at the construction site; Keep out of reach of children.

Observe all health and safety regulations on site.

Company Information

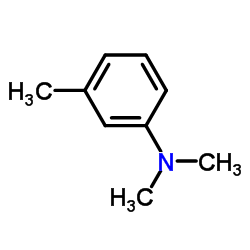

MIT-IVY INDUSTRY CO.,LTD is a manufacturer and exporter of fine chemical dyes & pharmaceutical intermediates in China.

Mainly produce aniline series products and chlorine series products.

MIT –IVY Chemicals Industry Co.,Ltd. is a leading manufacturerof chemical for 21 years with complete production equipment and meticulous management and maintenance of machinery.

We use advanced production technology and test methods to realize production, quality controlling to meet the standard. We have been approved by SGS, ISO9001, ISO140 01, GB/HS16949 and T28001.

Mit-Ivy main products include as the following:

API, pharmaceutical intermediates ,Dye intermediates, fine,speciality chemicals,Waterborne industrial paint and new energy materials.

Our main markets includes America, India, Africa, Indonesia, Turkey, South-east Asia, West Asia and so on. MIT-IVY Industry Main products shares 97% of the domestic market specializing in the production and management, We can supply the products with more competitive cost. with premium quality and price and welcome to consult. Our company has professional persons who major in chemical R&D and sicentific management, supply fine chemical products with high quality and close service, also supply custom-tailored products according to our clients’ requirement. We have a positive and self-motivated management work team with a common philosophy, caring and commitment through teamwork, our team strive to achieve success in delighting our clients and ourselves. we continuously innovate our products and improve our service, sales network. Hence, we initiate the first sale mode on net in China, which is the retail trade of small package bring along wholesale of diversified management modes. Our products are exported widely to South Korea, Vietnam, Australia, Europe and South America, highly recommended by our clients. We insist on the management creed “Market is our compass, Quality is our life, Credit is our soul”. Clients’ trust is our forward powder, their satisfaction is our struggling goal.

Brand Customer Service:

Our JIT customer service account team network in China develop and implement tailor-made concepts for the optimum supply of our customers with industrial and specialty chemicals.

Your advantages:

● Centralized customer service supports simplification of administrative procedures, resulting in time and cost saving.

● Our Chinese network and sophisticated logistics solutions ensure that chemicals of identical quality are supplied to customers with several manufacturing locations and contribute to security in planning and reliability of processes.

● Our processes are continuously optimized and adapted to our customers’ changing structures and requirements.

Superiority of Chemistry Logistics service:

Chemical logistic service is very professional and should be superior under UN regularity, especially for DGR Class series. We provide a special-purpose solution to optimize logistic and suitable packing group and labeling service for our principals. Our main Chinese ports with DGR chemical warehouses are to operate specialty chemical and apply all relative paperwork concerned.

Our distribution capabilities include:

● Flexible deliveries, intelligent solutions

● Anything from bulk shipments of thousands of tonnes down to the smallest shipment of packed goods and even samples.

● Bulk – storage and transport of powders and liquids – movement of goods in ships – powders and bulk liquids

● Pharma, feed and food storage to accredited standards

● Segregated materials by business unit and hazard classification

● Temperature controlled storage and transport

● Effective cost control

● Re-packing, drum filling, bagging, ripping and tipping

● Customer delivery KPI's on delivery fulfillment performance

If you are interested in getting more quotations,

please add WHATSAPP:0086-13805212761 or E-MAIL:info@mit-ivy.com

FAQ

Q. Are you factory or trading company?

A. We are a factory located in Fuan city, Fujian province, China .

Q. Are all colors are same price?

A.No, the price are different depend on the texture, availability, Ingredients and So on.

Q. Can you provide samples for quality checking before placing an order?

A. Samples are available upon request, but the shipping cost should be paid by customer.

Q. Is there a discount?

A. The discount will be given by the quantity.

Q. How about delivery time?

A. About 7-15 days after payment confirmed.

Q. What kind of payment terms you can accept?

A. We accept T/T, LC, Western Union and Paypal.